Home > Aluminium Processing Plant

Tilting Crucible Furnace – Precision Melting for Non-Ferrous Metals

Applications

Tilting crucible furnaces are widely used in:

- Aluminium die casting units

- Non-ferrous metal foundries

- Scrap recycling industries

- Brass and copper melting

- Jewellery and precision casting

- Alloy manufacturing

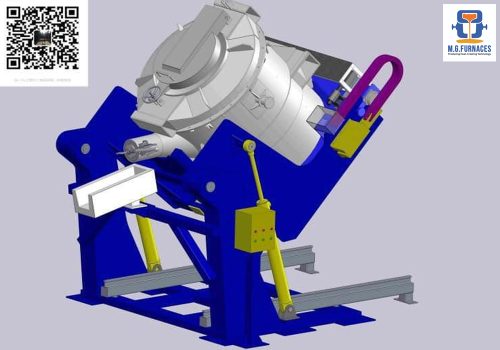

A Tilting Crucible Furnace is a highly efficient and operator-friendly melting system widely used in non-ferrous metal industries for melting aluminium, copper, brass, zinc, and other alloys.

Designed for easy pouring, accurate temperature control, and safe metal handling, it is one of the most preferred furnaces for medium-scale foundries, die-casting units, and recycling plants.

At M.G. Furnaces, we manufacture high-performance tilting crucible furnaces engineered for maximum efficiency, long life, and reliable pouring operation.

What Is a Tilting Crucible Furnace?

A Tilting Crucible Furnace is a melting furnace in which the crucible containing the metal can be tilted for controlled pouring.

The tilting system—manual, mechanical, hydraulic, or motorized—offers excellent operator convenience, improved safety, and smooth metal transfer.

It is ideal for melting small to medium metal batches with consistent temperature control.

Key Features of Our Tilting Crucible Furnace

- ✔ Easy & Controlled Pouring

The tilting mechanism provides smooth transfer of molten metal into molds, ladles, or casting machines. - ✔ High Thermal Efficiency

Specially designed combustion chambers and insulated linings ensure rapid melting and low fuel consumption. - ✔ Versatile Fuel Options

Available in:- Oil-fired

- Gas-fired

- Electric induction

- Electric resistance

- ✔ Robust Crucible Support System

Ensures uniform heating, reduced crucible wear, and extended lifespan. - ✔ Compact & User-Friendly Design

Occupies less space and minimizes operator effort during melting and pouring. - ✔ Precise Temperature Control

Advanced burners and digital controllers maintain consistent metal temperature throughout the process. - ✔ Enhanced Safety

Equipped with:- Heat-proof handles

- Emergency stop

- Flame-failure device

- Over-temperature protection

Technical Advantages

- Faster melting rates

- Lower oxidation and dross formation

- Stable molten metal quality

- Low maintenance

- Long refractory and crucible life

Why Choose M.G. Furnaces?

- ⭐ Custom-Built Designs

Available in different capacities, tilting mechanisms, and fuel systems based on your production needs. - ⭐ Sturdy and Durable Construction

Fabricated with premium-grade materials to handle high temperatures and continuous operations. - ⭐ Efficient Insulation System

Multi-layer insulation reduces heat loss and improves furnace lifetime. - ⭐ Fast Installation & Commissioning

Ready-to-use units with plug-and-play electricals and optimized burner settings. - ⭐ Reliable After-Sales Support

Maintenance, spares, upgrades, and technical guidance throughout the furnace lifecycle.

Available Capacities

- ✔ 50 kg ✔ 100 kg ✔ 200 kg ✔ 300 kg ✔ 500 kg ✔

Custom capacity available on request