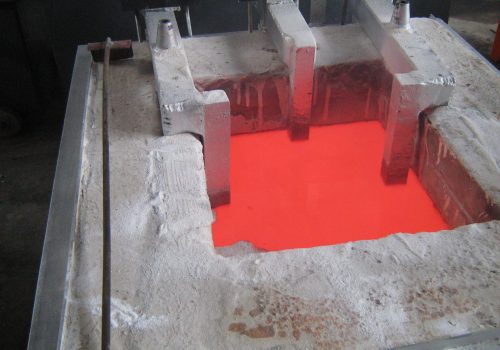

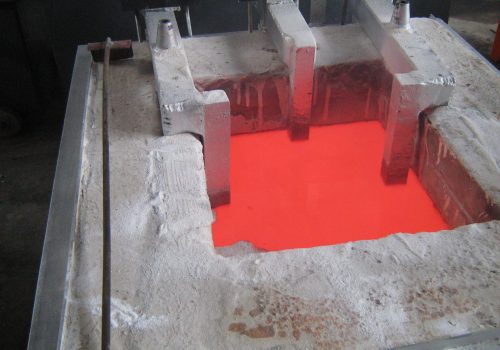

Salt Bath Furnace

Technical Specifications (Customizable)

| Furnace Type | Pot / Rectangular salt bath |

| Heating Method | Electric |

| Operating Temperature | As per salt composition |

| Capacity | Customized to process requirements |

A Salt Bath Furnace is a specialized heat treatment system that uses molten salt as the heating medium to deliver rapid, uniform, and controlled heat transfer to metal components.

This furnace is widely used for processes such as hardening, tempering, annealing, and surface treatment, where precise temperature control and minimal oxidation are critical.

Key Features

- Uniform & Rapid Heating: Molten salt ensures excellent heat transfer and consistent temperature throughout the bath.

- Oxidation-Free Processing: Components are protected from direct air exposure, resulting in clean surfaces and superior finish.

- Accurate Temperature Control: Maintains stable bath temperatures for repeatable heat treatment results.

- Robust & Corrosion-Resistant Construction: Designed to withstand aggressive salt environments and high operating temperatures.

- Safe & Efficient Operation: Equipped with advanced safety systems for controlled handling and operation.

Applications

- Hardening and tempering of steel components

- Surface heat treatment processes

- Automotive and precision engineering parts

- Tool and die manufacturing industries

Benefits of Salt Bath Furnace

- Delivers superior metallurgical consistency

- Reduces distortion and uneven heating

- Improves surface quality and hardness uniformity

- Shortens processing cycles and increases productivity

- Ensures repeatable, high-precision results

Process Capabilities

- Hardening

- Tempering

- Annealing

- Surface heat treatment

Why Choose Our Salt Bath Furnace?

Our Salt Bath Furnace is engineered for precision, safety, and durability.

Designed to meet the stringent demands of modern heat treatment operations, it delivers consistent performance, reduced oxidation, and enhanced component quality across a wide range of industrial applications.

.