Home > Battery Lead recyling plant

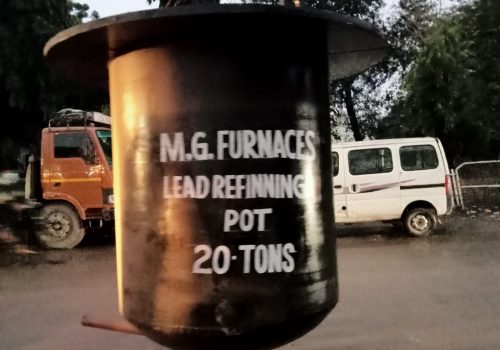

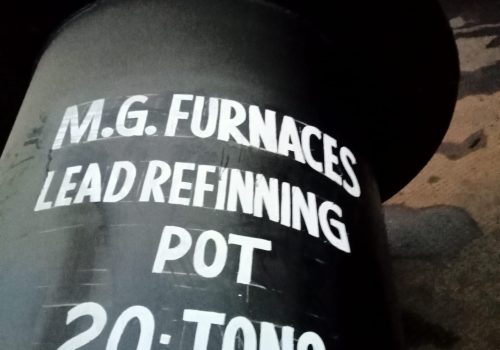

LEAD REFINING POT FURNACE

Technical Specifications (Customizable)

| Furnace Type | Stationary / Tilting pot furnace |

| Heating Method | Oil-fired / Gas-fired / Electric |

| Operating Temperature | Suitable for lead refining processes |

| Capacity | As per customer requirement |

A Lead Refining Pot Furnace is a robust and efficient thermal processing unit designed for refining molten lead by removing impurities and achieving the desired metal purity.

Widely used in secondary lead smelting and battery recycling plants, this furnace ensures consistent temperature control, uniform metal treatment, and high-quality refined lead output.

Key Features

- Heavy-Duty Pot Construction: Manufactured from high-grade steel with refractory lining to withstand extreme temperatures and chemical reactions.

- Uniform Heat Distribution: Ensures consistent heating and efficient refining across the molten lead bath.

- Energy-Efficient Design: Optimized insulation reduces heat loss and lowers fuel or power consumption.

- Easy Operation & Maintenance: Designed for safe slag removal, metal tapping, and routine maintenance.

- Customizable Capacity: Available in various pot sizes to match production requirements.

Applications

- Secondary lead refining plants

- Lead-acid battery recycling facilities

- Lead alloy preparation units

- Industrial lead purification operations

Benefits of Lead Refining Pot Furnace

- Achieves high-purity refined lead output

- Improves process efficiency and metal recovery

- Reduces fuel and operational costs

- Enhances operator safety and process control

- Supports continuous and batch refining operations

Why Choose Our Lead Refining Pot Furnace?

Our Lead Refining Pot Furnace is engineered for durability, thermal efficiency, and precise process control.

Designed to meet modern environmental and operational standards, it integrates seamlessly with lead pumps, conveyors, and casting systems to deliver reliable refining performance.

.