Home > Aluminium Processing Plant

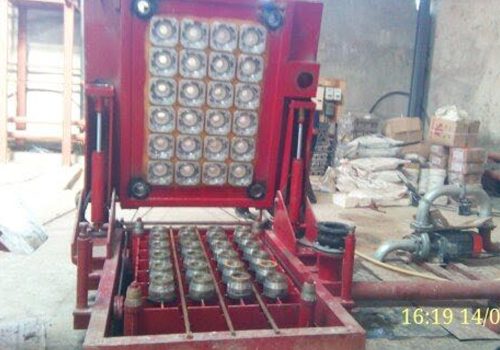

Hot Top Billet Caster

Applications

Hot Top Billet Casters are widely used in:

- Aluminium extrusion plants

- Alloy manufacturing units

- Non-ferrous metal processing

- Secondary aluminium recycling plants

- Foundries & casting plants

- Forging & machining industries

A Hot Top Billet Caster is an advanced continuous casting machine designed for producing high-quality aluminium billets, copper billets, alloy billets, and other non-ferrous metal billets with exceptional surface finish and internal soundness.

This system uses a hot-top casting technique that minimizes metal turbulence, reduces shrinkage, and ensures uniform billet quality from start to finish.

At M. G. Furnaces, we manufacture state-of-the-art Hot Top Billet Casters engineered for superior casting performance, high productivity, and long-term reliability—trusted by extrusion plants, alloy manufacturers, and metal processing industries worldwide.

What is a Hot Top Billet Caster?

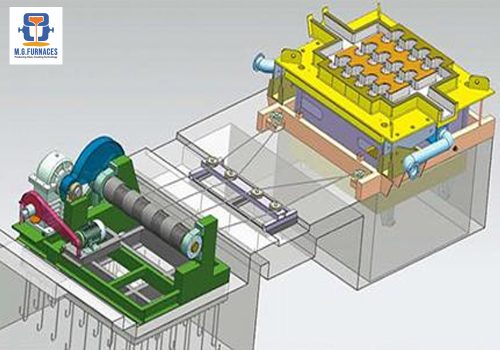

A Hot Top Billet Caster is a vertical direct-chill (VDC) casting machine where molten metal is fed through a “hot-top” insulated chamber.

This hot-top regulates the temperature of the metal during the initial solidification, ensuring smooth, stable, and defect-free billet formation.

It is widely used for casting billets of:

- Aluminium

- Aluminium alloys

- Copper

- Brass

- Bronze

- Other non-ferrous alloys

Key Features of Our Hot Top Billet Caster

- ✔ Superior Billet Quality

The hot-top chamber improves metal flow and reduces surface cracks, segregation, and porosity. - ✔ High Productivity

Produces uniform billets continuously with minimal downtime and high casting speeds. - ✔ Advanced Cooling Technology

Multi-zone water cooling system ensures consistent billet structure and reduced stress. - ✔ Automatic Metal Level Control

Sensors maintain accurate molten metal height for precise casting. - ✔ Robust Construction

Heavy-duty steel structure with long-lasting casting tables, moulds, and hydraulic systems. - ✔ Energy Efficient

Optimized design reduces metal loss, improves energy utilization, and lowers operating cost. - ✔ Touchscreen Control Panel

PLC/HMI-based system for:- Casting speed control

- Water flow management

- Temperature monitoring

- Alarm & safety interlocks

Technical Advantages

- Low billet butt formation

- Smooth surface finish, minimal scalping

- Uniform grain structure

- Reduced billet cracking

- Low turbulence casting

- Enhanced productivity with continuous operation

Why Choose M. G. Furnaces for Hot Top Billet Casters?

- ⭐ Fully Customizable Casting Line

We design machines tailored to your billet size, alloy type, and production capacity. - ⭐ Premium Quality Materials

All moulds, tables, and hot-top chambers built for long life under high-temperature operations. - ⭐ High-Level Automation

Reduces manual handling, improves quality, and enhances safety. - ⭐ End-to-End Support

Installation, training, spare parts, commissioning & service support across India & worldwide. - ⭐ Decades of Experience

Since 2009, we have been a trusted name in melting, casting, and thermal processing equipment for global clients.

Available Casting Sizes & Capacities

We offer Hot Top Billet Casters in multiple sizes:

- ✔ Billet Diameter

100 mm | 127 mm | 152 mm | 178 mm | 203 mm | 228 mm | Custom sizes - ✔ Casting Length

Up to 6 meters | 12 meters | Custom as required - ✔ Casting Capacity1–10 tons per hour (customizable)